Mechanical Balance

One of the common defects of rotating machines in the industry is the imbalance defect. In almost all industries and all rotating machines, including pumps, engines, generators, turbines, gearboxes, fans, etc., the most important vibration defect is imbalance. This defect is caused by various factors, including improper design, asymmetric materials, assembly errors, and conditions caused by operation such as wear, corrosion, and sedimentation. When there is an imbalance in the moving parts of the equipment, a centrifugal force proportional to the second power of the speed is produced, which is restrained through the bearings. Therefore, if these forces are permanently present on the bearing, it will cause their premature wear and failure. Another disadvantage of equipment imbalance is the introduction of periodic forces to machine components such as axles, couplings, screws and other connections, and their failure due to fatigue.

Accelerometers are usually used to detect imbalance. In this way, they install the accelerometer on the bearings of the device in such a way that they can measure the vibrations in the direction perpendicular to the axis.

The network accelerometer and the miniature accelerometer made by the Saba watch company have the ability to be installed on the balance devices and the signal is available in the computer through the vibration analyzer (DPS-DAQ). Then, using NI LabVIEW open source software provided by the company, different balance algorithms can be implemented. This method is very economical and is cheaper than similar methods with high quality.

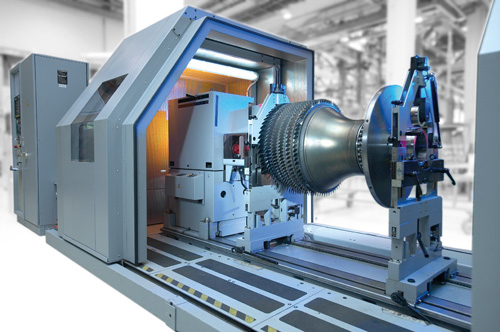

بالانس کارگاهی

بالانس کارگاهی بالانسر همراه

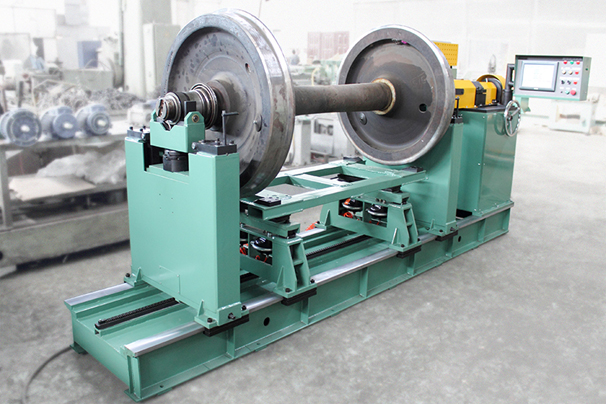

بالانسر همراه بالانسر اکونومی

بالانسر اکونومی شتابسنج شبکه

شتابسنج شبکه شتابسنج مینیاتوری

شتابسنج مینیاتوری

شتابسنج عمومی

شتابسنج عمومی